Workshop services

Reduced downtime, guaranteed!

We offer 3 options: Outright sale of components, standard repair of components (strip & quote) and service exchange.

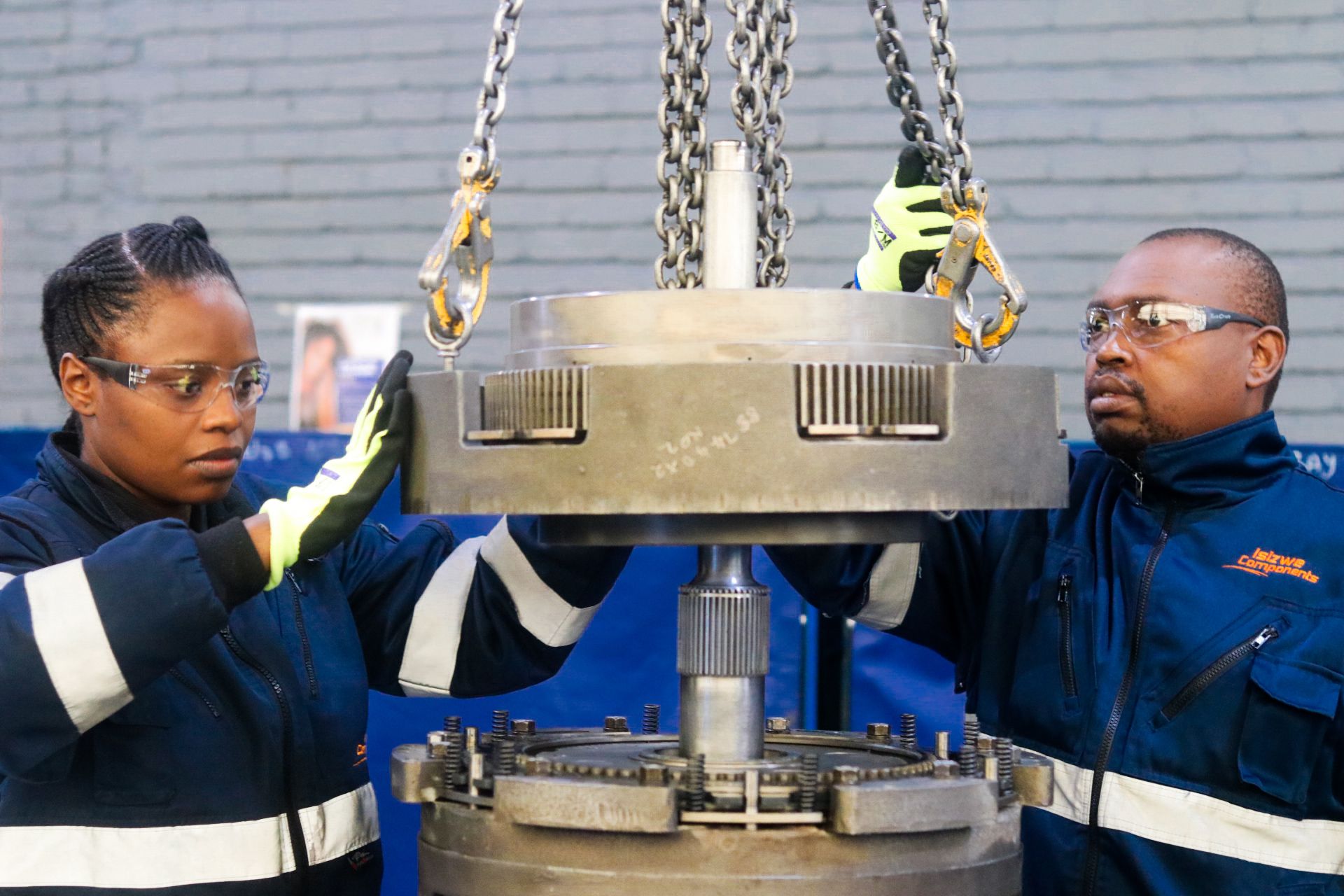

COMPONENT OVERHAUL

Isizwe Components is fully equipped to provide comprehensive, high-quality component overhauls. Leveraging innovative engineering practices, our expert technicians ensure that every component is restored to meet the most thorough standards of quality and performance.

HYDRAULIC PUMPS & MOTORS

We specialize in repairing & maintaining pistons, gears, vane pumps and hydraulic cylinders. We offer a fully equipped hydraulic department that specialises in the servicing and repair of hydraulic components.

This department plays a crucial role when it comes to major hydraulic flushes and machine rebuilds.

Hydraulic pumps & motors are delivered with a test certificate to assure our customer that a quality service has been delivered.

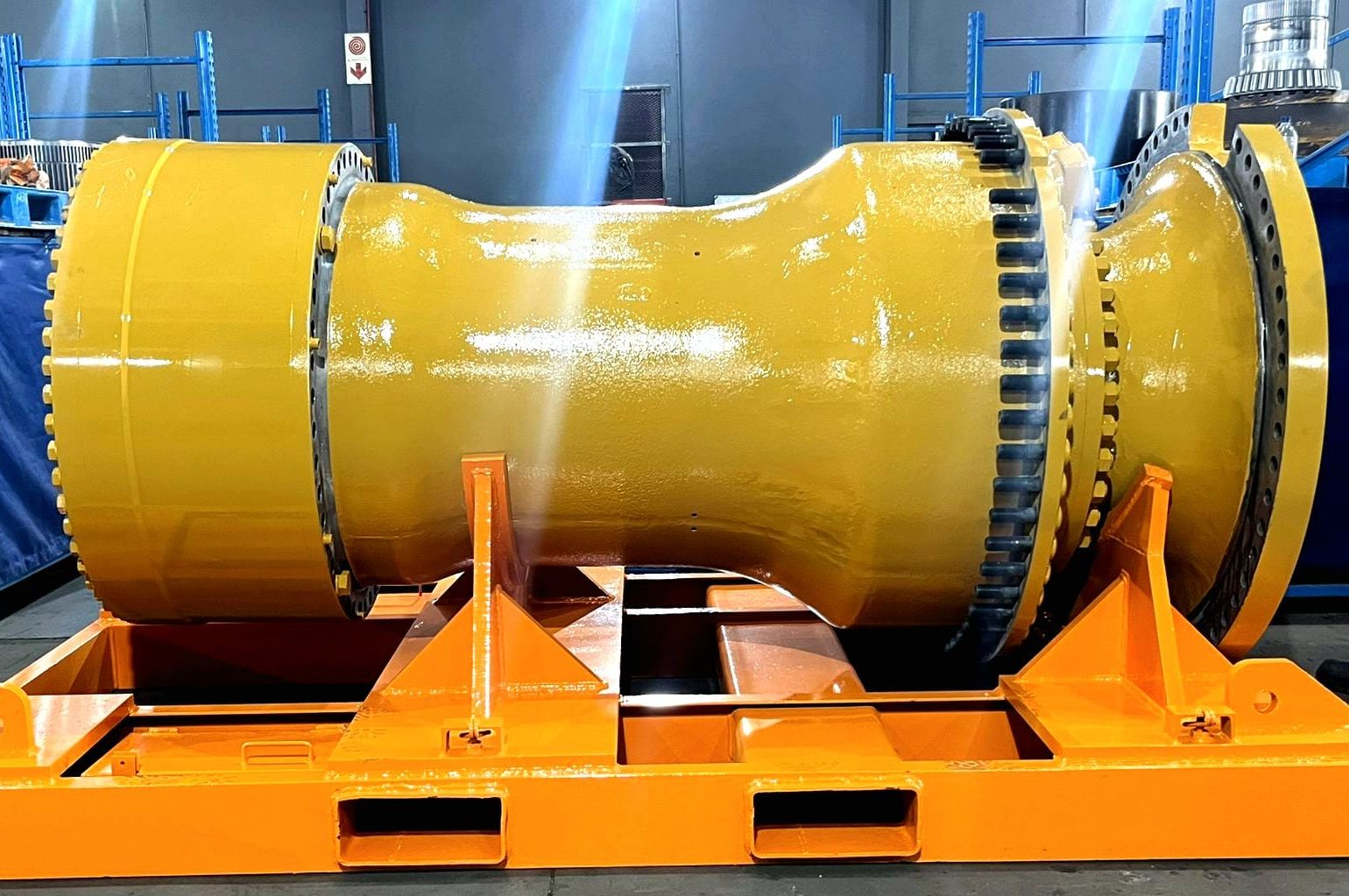

TRANSMISSIONS & TORQUE CONVERTERS

Transmissions and torque converters are supplied as plug-and-play solutions. Transmissions and torque converters are essential components to restore, it breathes new life into heavy machinery, ensuring they deliver power and reliability.

WHEEL STATIONS

We test wheel stations and final drives, handle critical on-site installations, and supply service exchange units, ensuring the fastest turnaround time. We specialize in maintaining, repairing, and upgrading earthmoving wheel stations, brake groups, and front hubs, offering thorough inspections, part replacements, and full reconditioning to ensure optimal performance, reliability, and cost-efficiency. All of our wheel stations and final drives are tested with the latest advanced equipment to ensure duo-cone seals have no leaks and reach maximum life. Brakes are tested to correct specifications before they are fitted.

24/7 FIELD SERVICE

Equipment repairs and breakdowns, diagnostic testing and technical analysis with evaluations and recommendations.

Our field service team is available to respond 24/7. We provide the following services:

- Equipment repairs on breakdowns.

- Diagnostic testing on all Caterpillar machines

- Technical analysis evaluations and recommendations

Apart from commissioning of newly installed components, our field service team assist clients in man-on-site and ad-hoc breakdown support.

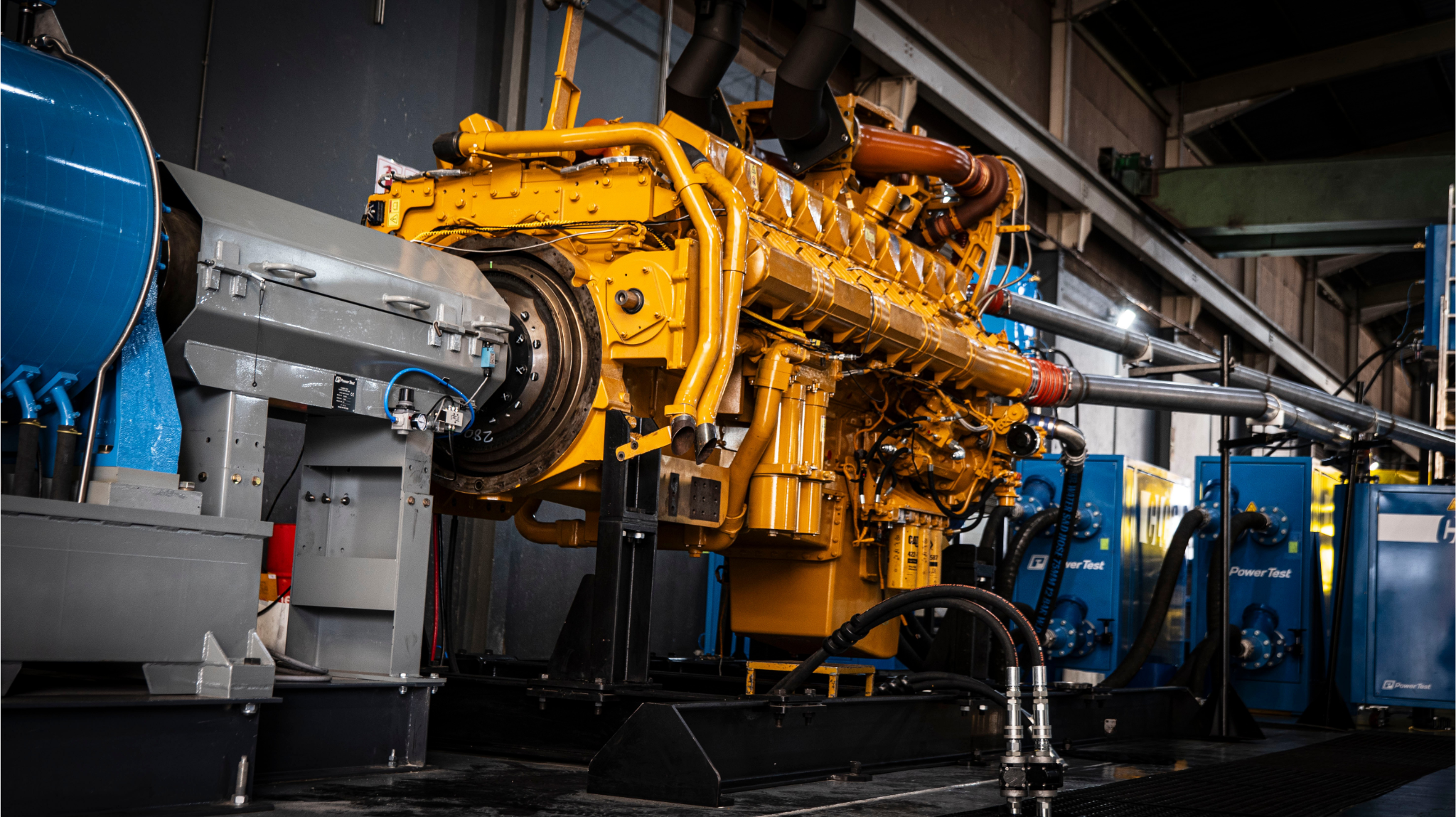

ENGINE REBUILD DEPARTMENT

At our Engine Rebuild Department, we pride ourselves on possessing extensive knowledge and expertise in constructing high-powered mining equipment engines. Our specialisation lies in performing zero-hour rebuilds, ensuring your engines are restored to their original factory specifications. We recondition and rebuild all major engines and guarantee optimal performance, reliability, and longevity for your machinery. Trust us to power your mining operations with precision and excellence.

REBUILDS CENTRE

Our rebuilds department is fully equipped to rebuild all types of mobile mining equipment up to 230 ton dump trucks.

We pride ourselves on possessing extensive knowledge and expertise in constructing mining machinery for performance & dependability. At Isizwe Components, we take pleasure in breathing new life into heavy machinery, ensuring they perform like new, if not better.

Quality, precision, and excellence are what we stand for! We offer repairs, component change outs, 0 hour rebuilds and partial rebuilds.

AUTO ELECTRICAL DEPARTMENT

Our auto electrical department offers a full range of auto electrical services, from harness building and rewiring to troubleshooting, testing of Electronic Control Units, sensors and batteries.

DYNAMOMETER BAYS

We have two Dyno testing facilities, our Dyno bays are designed and built to world class standards. With an in-house, dedicated dyno bay & team we ensure faster turnaround times for engine and transmission builds, allowing each unit to be thoroughly tested.

Our dynamometer bays are not limited to engine sizes.

COOLING DEPARTMENT

Our dedicated radiator and cooler department is equipped with specialised and custom designed equipment to test radiator cores and oil coolers. This department also builds complete cooler packs for machine rebuilds or per customer request.

We are committed to delivering eco-friendly, sustainable, and innovative cooling solutions that exceed expectations. As leaders in the cooling industry, we specialise in providing top-quality, energy-efficient components designed to reduce carbon emissions and save our customers money. Our skilled team works closely with clients to offer tailored cooling solutions that make a positive environmental impact. With superior quality, advanced technology, and exceptional service, we aim to be a trusted partner for all your cooling needs.

IST ACADEMY

The International Specialized Training Academy was established at the end of 2021 and is based on the same premises as Isizwe Components.

The academy was designed and built to standards never-before-seen by the industry by embracing technology and modern training methods. As the academy is directly linked to the industry, it is up to date with the latest trends and requirements in the field. There is a direct channel between the Quality Control Plan and warranty system of Isizwe and the academy. This allows the Academy to develop specialised solutions to address problems identified and in so doing, improve the efficiency and ability of the Isizwe team.

The Academy is fully accredited with the Quality Council for Trades and Occupations (QCTO). Currently our scope includes:

- Occupational Qualification: Heavy Equipment Mechanic

- Occupational Qualification: Transportation Electrician (Automotive Electrician)

- Occupational Qualification: Solar Photovoltiac Technician

For more information, you can get hold of the academy directly:

- www.ist-academy.co.za

- [email protected]

- 010 109 1578

- 33 Brewery Road Isando

BOILER SHOP

Our expert team specialises in undercarriage repairs & solutions, bucket refurbishments, diesel tank repairs, side frame repairs and more, providing a wide range of services to keep your equipment in optimal condition.