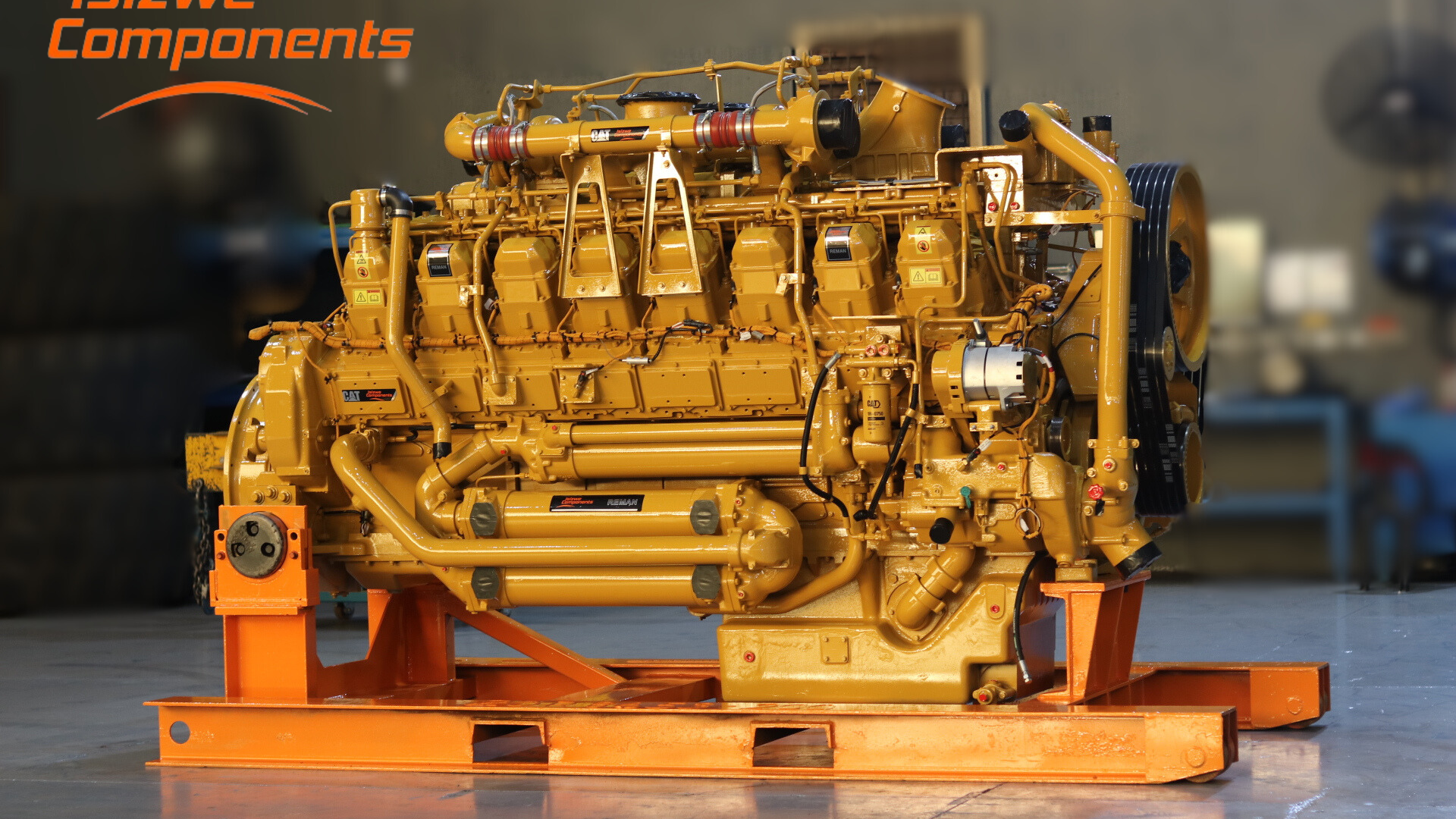

Complete Rebuilds on Earthmoving Components for Mining Machines

In the mining industry, earthmoving machines are the backbone of operations. These machines are subjected to harsh conditions and heavy loads, leading to wear and tear of their components. This necessitates regular maintenance and, in some cases, complete rebuilds of these components. Complete rebuilds involve disassembling the machine, inspecting each part, repairing or replacing worn-out components, and then reassembling the machine. This process ensures that the machine operates at its peak efficiency and prolongs its lifespan. Some of the key components that often require rebuilds include the engine, transmission, hydraulic system, and undercarriage. The rebuild process begins with a thorough inspection to identify worn-out parts. The machine is then disassembled and each part is cleaned, inspected, and measured against manufacturer's specifications. Worn-out parts are replaced with new or remanufactured parts. The machine is then reassembled, tested, and repainted to look like new. Complete rebuilds can extend the life of earthmoving machines by several years. They also improve the machine's performance, reduce downtime, and lower the total cost of ownership. Moreover, rebuilds are environmentally friendly as they reduce the need for new machines. In conclusion, complete rebuilds of earthmoving components for mining machines are a cost-effective and sustainable way to maintain the performance and extend the life of these machines.